January 06, 2019

The Best Wood For Garage Cabinets

A garage is a very good place to work. We believe that just like you have always put in the effort into making your home or office look presentable, you should do the same in your garage.

One of the best pieces of furniture that you can use and enjoy in your garage is a cabinet. This is because of its usefulness in many respects.

A garage cabinet can be used to store many materials so that they aren't exposed to the outdoor elements.

But since there are many materials that can be used to make a garage cabinet, wood being one of them, you must be very keen when you wish to install one in your garage.

The type of work you do in the garage will dictate the kind of wood you should choose for your cabinet. You have to take into account the factors of durability, cost, and nature of the wood. Possible candidates might be poplar and oak.

With this in mind, you will be able to choose the best wood for your garage cabinets.

But in general, what is be the best wood to use?

In our opinion, the answer is plywood.

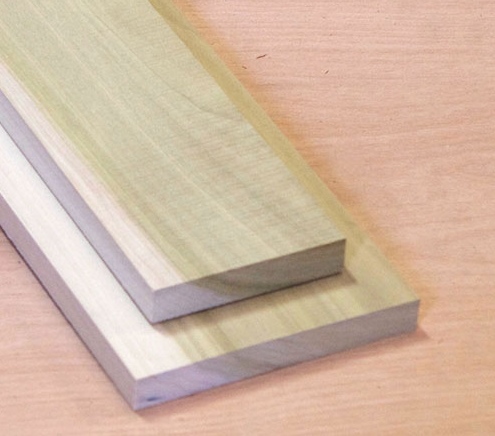

Plywood

Plywood so far has proved to be one of the best woods to use in building a garage cabinet.

Have a look at this awesome video:

There are many reasons as to why we recommend it as the best. If you have decided to install a cabinet in your garage, then you will need to use a material that possesses useful qualities, keeping in mind that some external factors might affect the lifespan of your cabinet.

Why plywood?

- Plywood is strong, which make it suitable for holding heavy garage materials.

- It is relatively cheap compared to other woods, and thus you won't have to spend as much.

- It’s smooth and can improve the general look of your garage.

- It lacks knots which minimize the number of patches on the cabinet.

- It’s readily available in most hardware stores, so you won’t have to drive around the city looking for it.

Conclusion

There are other words that can be used to build garage cabinets, but we think plywood is the best. Give it a try and see how it turns out!

Posted by: woodworkworld at

03:17 AM

| No Comments

| Add Comment

Post contains 383 words, total size 4 kb.

September 03, 2018

6 Kreg Screw Substitutes

If, like many woodworkers, you're interested in American-style carpentry, and you're watching carpentry videos on YouTube, you've probably heard about Kreg screws.

These pocket hole jigs make it possible to assemble wooden items using hidden screws in a very simple and fast way.

They have been used for many years in the United States and Canada. It is a device that needs several parts to function properly.

Today, many experienced carpenters and cabinetmakers disapprove of the use of the Kreg jig as it is considered too amateurish and comes at a high price. It is also less safe as it loosens often and can open the furniture unexpectedly.

Because of these downsides, many woodworkers are looking for substitutes for Kreg screws. Once they find one and they assemble the right materials (perhaps unwarping some wood), they're good to go!

Here are six alternatives to Kreg screws that are being adopted by woodworkers:

- Washer Head screws

- Square Drive

- Quick screws

- Philips Round Head

- GRK Star Drive

- Phillips Flat Top Washer Head Screws

Types of Pocket Hole Screws

Screws are a very interesting means of attachment. To know what type of screw to use, you must evaluate the work to be done and choose what is best for you.

For wood or agglomerates, the most commonly used screw is the countersunk flat screw. It is a screw that has the advantage of being compatible with the dowels and can be tightened manually or electrically.

There is also the countersunk head screw, more decorative than the first. Countersunk head screws are best used for chipboards, coated woods, hardwoods, softwoods, wood assemblies, balcony construction and any load bearing elements.

They are easy to screw, thanks to their deep impression, and tend not to split.

The round head screw is used for fixing a metal part on wood.

For fixing plasterboard, it's ideal to use a trumpet head screw. You will save time because it is very fast.

Lag screws are intended for complicated and difficult work.

Carpentry screws with the countersunk head are best suited for wood frames, for example, in joining of structures such as timber frames, wooden houses, carports, winter gardens and playground equipment.

They are easy to use thanks to their optimal power transfer and cutting quality. They have the perfect finish and require no pre-drilling. They are available in countersunk head or flat head versions.

There are plenty of ways to go if you don't want to use Kreg screws. Good luck!

Posted by: woodworkworld at

03:52 PM

| No Comments

| Add Comment

Post contains 416 words, total size 4 kb.

August 07, 2018

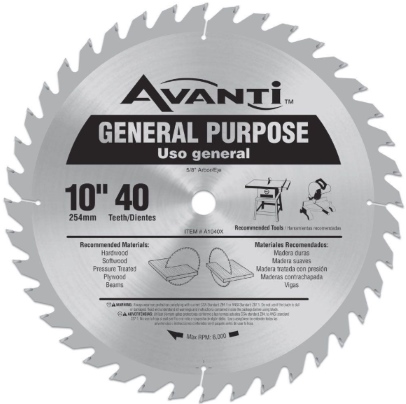

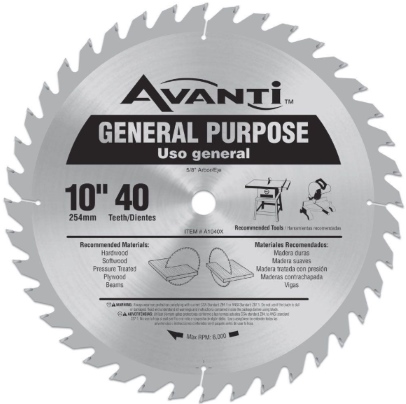

Are Avanti Saw Blades Any Good?

Avanti saw blades are economical, high-performance blades recommended for timber wood, pressure treated wood, beams and oriented strand board.

They are made up of high-quality steels and carbide reinforcements. These blades can be re-sharpened to extend their working life.

When you're looking to achieve beautiful and smooth cuts on plywood, then one of your top choices should be Avanti Saw blades.

When two inferior saw blades cost as same as one decent saw blade, then it doesn’t matter what benefits they offer; the decent blade would be the way to go. Avanti saw edges provide the excellent finish suitable for all type of plastics and other furniture at home.

Are Avanti saw blades worth it? In my experience, yes; their performance is on par with blades from top brands like Freud and DeWalt.

Having said that, when you're shopping for saw blades, it's important to look at customer reviews (like these) if possible.

Let’s take a look some factors to consider when deciding whether or not Avanti saw blades are ideal for you:

1. Strength

Strength is one of the most important factors to determine the type of blade to get.

Avanti blades are certainly strong; they are reinforced with high-quality steel and equipped with sharp teeth. This particular design makes them a potent tool to work with.

2. Cut Smoothness

Avanti blades are circular blades with 140 teeth designed to yield a smoother cut.

It is an excellent design for achieving a smooth cut. The metal is concentrated near the blade point to provide smooth functioning.

3. Durability

Avanti fine-finished blades with carbide topping are designed to provide more strength than other saw blades. They have a special rim coating to reduce binding and drag.

These blades are designed specifically for professional contractors, with a thin slit being made by the cutting edge.

Woodworking and DIY is a terrific hobby, but taking advantage of the best saw blades on the market will ensure you get great results with your work. If you're looking for a more advanced cutting alternative such as CNC machining, I would recommend getting more info on carve your creation.

With the benefits discussed above, Avanti saw blades are clearly good enough to be relied upon in the workshop.

When operating these blades, you should always eye protection, feather boards and hold down devices properly.

Posted by: woodworkworld at

06:18 PM

| No Comments

| Add Comment

Post contains 395 words, total size 4 kb.

July 30, 2018

3 Ways To Add Color To Shellac

Shellac is typically used by people who work with wood to give the final product an elegant finish.

It improves the beauty of your furniture without causing any damage to the wood.

Why add color to shellac?

You may want to add color to shellac if the surface in question is already coated with clear shellac and you want to touch up the finishing.

This can be done by mixing amber and clear shellac to get a color that resembles the shellac finish. This method of adding color to shellac is normally employed when an old floor is being renewed.

This leads us to the first method of adding color:

1. Amber Shellac

Amber shellac can be used to add color.

To lighten the shade, you add clear shellac to it, and to deepen the shade, you add more amber shellac to the mixture.

Ensure that you shake the mixture well and incorporate the shellac completely.

Brush the mixture on a separate (preferably disposable) surface and check the color. If there is a difference between the new and the old shellac coat, add more amber or clear shellac to get the color you want.

Other materials that can be used to add color to shellac are:

2. Dyes and Stains

Alcohol-based stains and dyes can also be used to add color to shellac.

If you want a blue/dark green color, you should add a black stain to amber shellac. And if you want to impart an intense color to the shellac, you can use a dye or stain to achieve the desired result.

3. Universal Colorants

Universal colorants are used to add a dark shade to shellac. Up to 6 oz of a universal colorant is added to each gallon of shellac.

You should mix the shellac well so that the colorant can dissolve completely. To ensure thorough mixing, use a mechanical shaker.

Conclusion

Shellac has the great feature of matching the previous coating, making it the perfect material to fix superficial scratches and blemishes on wooden furniture or surfaces.

You can get shellac in different colors, like amber, garnet and clear; these can get combined in different proportions to give the desired color. You can also use different dyes or stains to produce nearly any color you want for your shellac.

You can read more about this topic here.

Now you know the best ways to color shellac. Which one will you choose?

Posted by: woodworkworld at

02:27 PM

| No Comments

| Add Comment

Post contains 411 words, total size 4 kb.

July 28, 2018

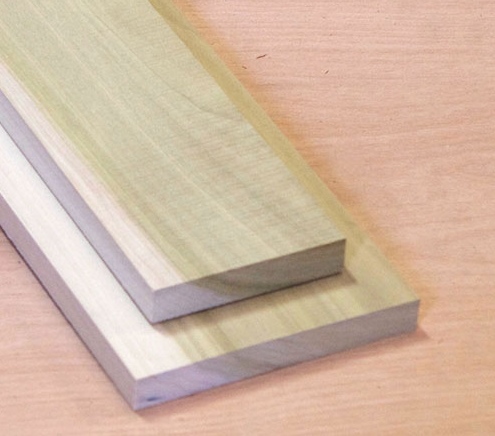

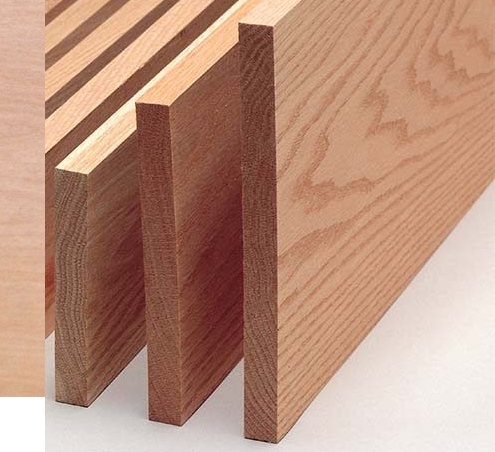

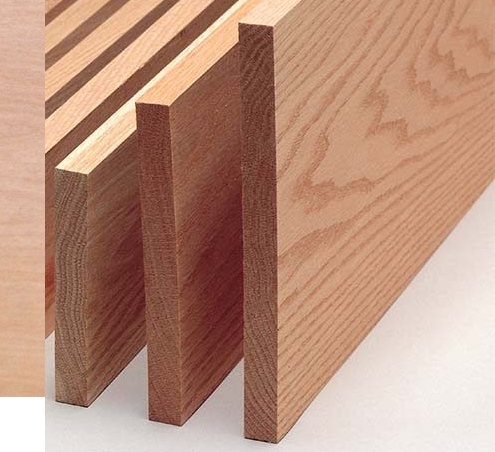

Poplar Vs. Oak — What's The Difference?

Poplar and oak are the two main hardwoods that are used for domestic purposes.

They are different in several key areas:

- appearance

- density

- workability

- grain

- strength

- cost

- color

These are the main factors that are responsible for differences between the two hardwoods.

Let's go into each of them in a bit of detail:

1. Appearance

Poplar is mostly white with green and yellow strips. Other times, these strips may be black or purple. Poplar is considered to be bland in appearance because it has little to no grain pattern.

2. Density

Poplar has a lower density than oak. Poplar is ranked 540 on a scale that ranks all wood for density while oak is ranked 1,290 on average.

Conclusion

Poplar is generally lighter, easier to work with and cheaper than oak, and is mostly for structural components like drawers, struts, and guides. On the other hand, oak can work best for stained cabinets.

1. Appearance

Poplar is mostly white with green and yellow strips. Other times, these strips may be black or purple. Poplar is considered to be bland in appearance because it has little to no grain pattern.

On the other side, oak varies from pinkish red to light amber. Oak also has complex grain patterns that look like flames.

Both poplar and oak can be stained; however, oak reflects a more vibrant and deeper tone than poplar.

2. Density

Poplar has a lower density than oak. Poplar is ranked 540 on a scale that ranks all wood for density while oak is ranked 1,290 on average.

This difference in density implies that oak is more cumbersome to work with than poplar, whether with a miter saw (recommendations on this page) or some other tool.

The density difference also means that oak is much more brittle than poplar, and thus when curving similar pieces oak will crack or shatter more easily than poplar.

3. Workability

Poplar is more comfortable to cut, nail, sand, and mill than oak.

3. Workability

Poplar is more comfortable to cut, nail, sand, and mill than oak.

The resilience of poplar yields to router bits, saw blades, knives, and chisels having an easier time as compared with the brittle consistency of oak.

Regular saw blades will work well on poplar, but oak will often dull these blades leading to chattering, splintering and burning on a table saw.

4. Carving

Poplar works best for the hobbyist who manipulates woods to make turnings, scrolls, small crafts, and models. The resilient and soft wood yields easily to carving tools, files, rotary tools, knives and any other equipment that may be used for carving.

4. Carving

Poplar works best for the hobbyist who manipulates woods to make turnings, scrolls, small crafts, and models. The resilient and soft wood yields easily to carving tools, files, rotary tools, knives and any other equipment that may be used for carving.

Oak, with its brittle and hard nature, is likely to chip and splinter when carved. You also needs more force when carving oak than you do with poplar.

Conclusion

Poplar is generally lighter, easier to work with and cheaper than oak, and is mostly for structural components like drawers, struts, and guides. On the other hand, oak can work best for stained cabinets.

Poplar is mostly used for components of furniture that cannot be seen.

Posted by: woodworkworld at

03:59 PM

| No Comments

| Add Comment

Post contains 403 words, total size 4 kb.

Wood Species From Around The World

|

A western Australian furniture manufacturer created this informative infographic. It clearly illustrates the use, distribution, tree size and workability of 17 wood species.

I hope you find it helpful.

Posted by: woodworkworld at

02:05 PM

| No Comments

| Add Comment

Post contains 37 words, total size 1 kb.

<< Page 1 of 1 >>

31kb generated in CPU 0.047, elapsed 0.0734 seconds.

30 queries taking 0.0623 seconds, 53 records returned.

Powered by Minx 1.1.6c-pink.

30 queries taking 0.0623 seconds, 53 records returned.

Powered by Minx 1.1.6c-pink.